| CAS No.: | - | EINECS No.: | - |

| Product name: | Hafnium carbide powder |

Model Number: | NM-009 |

| Appearance: | ash black powder | Brand Name: | RWCHEM |

| Shape: | Powder | Application: | Industry |

| Dimensions: | 50-800nm | Material: | Hafnium carbide powder |

| Chemical Composition: | Hafnium carbide powder | Purity: |

99.6%

|

| Place of Origin: | Shanghai, China (Mainland) | Average particle size (nm): | 800 |

| Specific surface area (m 2 / g): | 8.30 | Bulk density (g / cm 3): | 4.20 |

Technical parameters

|

Products are classified

|

Average particle size (nm)

|

Purity (%)

|

Specific surface area (m2 / g)

|

Bulk density (g/cm3)

|

Polymorphs

|

Color

|

|

Nanoscale

|

-

|

-

|

-

|

-

|

-

|

-

|

|

Submicron

|

800

|

>99.6

|

8.30

|

4.20

|

cubic

|

ash black

|

Main characteristics

Ultrafine hafnium carbide powder by variable current laser ion beam, chemical vapor deposition powder high activity, surface energy is large, widely used in powder metallurgy, hafnium carbide (HfC) = 185.501, 6.47% carbon, belongs to the crystallization of sodium chloride type cubic crystal system, theoretical density of 12.7 g/cm3, melting point 3890 ℃, the highest melting point is a single compound. Volume resistivity Ω 1.95 x 10-4 cm (2900 ℃), thermal expansion coefficient of 6.73 x 10-6 / ℃. Has high elasticity coefficient, good electrical and thermal conductivity, small thermal expansion coefficient and good impact resistance performance, superfine hafnium carbide with many compounds (such as ZrC, TaC) form a solid solution.

Apllication

1 superfine hafnium carbide powder is suitable for the rocket nozzle throat materials field, it is important to metal ceramic material;

2 powder metallurgy;

3 high temperature resistant structure.

4 nanometer zirconium carbide can be applied to the coating, as a high temperature resistant coatings, improve the surface properties of materials;

5 carbon carbon composite functional materials modifier of zirconium carbide (ZrC) : used for modification of carbon fiber can greatly improve the intensity of carbon fiber, improve the fatigue resistance and wear resistance and high temperature resistant performance. Through the modification of carbon fiber after testing, the indicators are surpass international level, the current widely used aviation modification of carbon fibre material, the effect is very obvious.

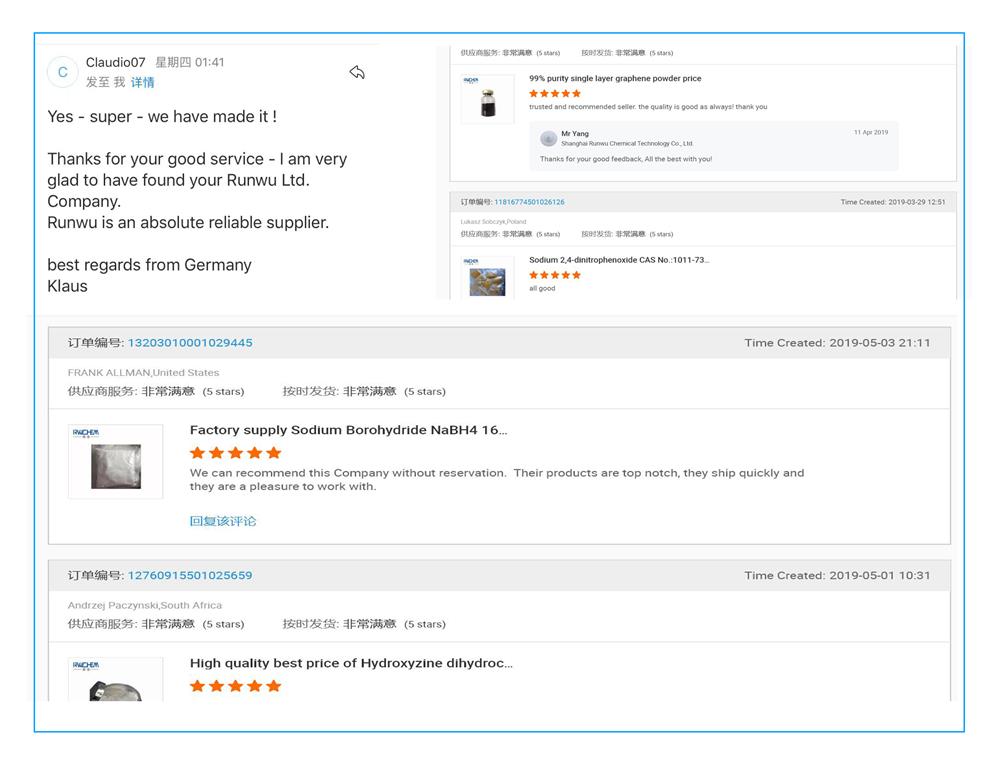

Shanghai Runwu Chemical Technology Co. Ltd is a chemical enterprise product R & D, production, sales, as one of the detection. We depend on strong research ability and mature technology, have a rapid rise in the chemical industry, relying on science and technology development, to provide customers with high-quality products is our constant pursuit.

We mainly dealing with organic intermediates, noble metal catalyst, nano materials, rare earth. These materials are widely used in chemistry, medicine, biology, environmental protection, new energy, etc.

With first-class product quality and superb technical services, We have won the praise of customs. At the same time, in the development, our company adhere to cooperation with domestic and foreign companies, scientific research institutions, universities exchange, in order to improve R & D and production capacity, committed to providing customers with more quality products and services.

Free samples

Free samples for quality evaluation available

Factory

Factory audit welcome

Order

Small order acceptable